Understanding how UV printing works

While conventional printing enables the ink to dry naturally on the paper, UV printing has its unique process. First off, UV inks are used rather than conventional solvent-based inks. Also known as UV RIP printing, UV printing is a printing method that utilizes UV curing ink to print on various materials. This extremely versatile printing process is quick, efficient and extremely effective.

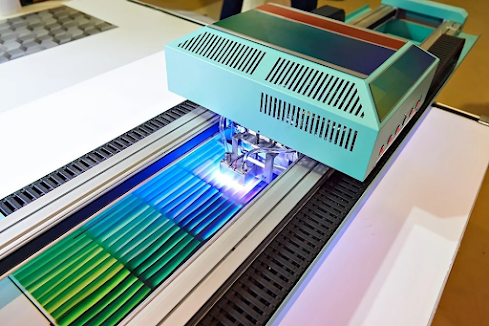

UV printing is a digital printing type where UV lights are used to cure ink as it is printed onto the surface. Rather than conventional, solvent-based inks, UV printing utilizes UV inks. As the printer distributes ink on the surface of the printed material, a UV light follows close behind, curing the ink right away. This instant curing means that dots of wet ink do not have the chance to spread once printed, providing much finer attention to detail.

Following are the technology used in UV printing:

UV inks are typically flexible, enabling them to print curved lines or onto elastic materials. During the UV printing procedure, the UV ink is cured right away, eliminating the need for a drying stage in the process and enabling the printed object to be used instantly.

UV printers use print head technology to deliver ultra-precise ink placement. Microscopic piezoelectric elements are mounted behind the print head nozzles, and an electrical charge is applied. This charge makes the elements flex, causing extremely precise amounts of ink to be ejected with a high level of control. The print head creates perfectly spherical dots of diverse sizes, offering great control over color density, print quality, and finish.

UV lamps are used to cure the UV ink once printed instantly. This speeds up the UV printing process considerably. The UV lamps are cool-running hard-wearing, safe, ozone-free, and cost-effective LED lamps. They also do not take time to warm up.

Also known as spot varnish or spot gloss, spot UV printing is a method for coating printed products. A varnish is placed onto the printed material and this is then cured using UV light, to make a clear, shiny layer.

This technique is most effective on color-printed products, helping to enhance shine while protecting the color from damage and moisture. It is frequently used to choose particular elements of the design to create contrast and impact. Spot colors are used to recognize the specific area of the design that needs to be coated. One of the appeals of UV printing is that it can be used to print on a wide range of materials and products. In fact, this printing method can be used to print on nearly any material – excluding waterproofed and oil-surfaced materials.

Also Read :- Top 4 different types of printers in 2022

.jpeg)

Comments

Post a Comment